Closed cell spray foam performs best in extreme climates due to its high thermal resistance, low moisture permeability, and structural reinforcement properties. It provides a consistent air seal, reduces heat transfer, and performs reliably in both high-heat and sub-zero conditions. In areas with extreme seasonal variation or persistent humidity, closed-cell insulation outperforms open cell alternatives.

Installation teams have observed that closed cell spray foam retains insulation value even under pressure from temperature fluctuations, wind-driven rain, and ice. With proper thickness and placement, it protects against condensation, energy loss, and material degradation.

Rib Spray Foam Company brings years of field experience applying spray foam in harsh mountain winters and hot Colorado summers, providing firsthand insight into long-term product performance.

Comparing Spray Foam Types for Extreme Climates

| Feature | Closed Cell Spray Foam | Open Cell Spray Foam |

|---|---|---|

| R-Value per Inch | R-6.0 to R-7.0 | R-3.5 to R-3.8 |

| Vapor Barrier | Yes | No |

| Air Seal Quality | High | Moderate |

| Moisture Resistance | Strong | Weak |

| Structural Rigidity | Increases wall strength | Soft and flexible |

| Best Use Case in Extremes | Exterior walls, roofs | Interior-only areas |

| Cost per Board Foot | Higher | Lower |

| Performance in Humid Cold | Excellent | Poor |

| Shrinkage Risk | Low | Moderate |

| Lifespan | 30+ years | 15–20 years |

Technical Specifications by Foam Type

| Property | Closed Cell SPF | Open Cell SPF |

|---|---|---|

| Density | 2.0 – 2.5 lb/ft\u00b3 | 0.4 – 0.5 lb/ft\u00b3 |

| Water Vapor Permeance | < 1 perm at 1.5 inch | 10+ perms at same thickness |

| Air Leakage Rate | Near zero | Minimal but present |

| Application Thickness Range | 1–3 inches/pass | 3+ inches/pass |

| Tensile Strength | 30–40 psi | 5–10 psi |

Data Sources:

- Oak Ridge National Laboratory (ORNL), 2023 report on SPF performance

- Building Science Corporation, “Moisture Management in Walls” (2022)

Regional Factors That Affect Performance

In Colorado’s high-altitude and semi-arid climate, insulation must handle UV exposure, snow loads, freeze-thaw cycles, and low winter humidity. Rib Spray Foam Company has observed that closed cell foam retains adhesion and insulative value through winter wind gusts exceeding 50 mph and during multi-day snow accumulation.

Areas with heavy rainfall or high coastal humidity—such as the Gulf Coast or Pacific Northwest—see higher performance decline in open cell foam unless paired with vapor retarders. Cold-weather states like Minnesota or Wyoming report condensation buildup with open cell foam in unvented attics unless mechanical ventilation is added.

Things to Consider Before Making a Decision

- Building Type: Closed cell performs better in metal structures, pole barns, and crawl spaces due to moisture control and rigidity.

- Budget vs. Long-Term Value: Upfront cost is higher for closed cell, but savings in HVAC loads and structural reinforcement are often substantial.

- Space Constraints: Closed cell foam provides more R-value in less thickness, suitable for areas with depth limitations.

- Moisture Levels: High humidity environments benefit from the impermeability of closed cell foam.

Bonus Tip: Installers recommend confirming local code requirements for vapor barriers and thermal ignition barriers before selecting a product.

We Offer Reliable Insulation Services for All Conditions

Rib Spray Foam Company provides installation services proven effective in tough weather and structural conditions:

- Closed Cell Spray Foam: High-density insulation suitable for demanding environments with tight air sealing and moisture resistance.

- Crawl Space Spray Foam: Helps prevent ground moisture intrusion and improves floor temperature stability.

- Pole Barn Spray Foam: Maintains indoor conditions with added structural support in agricultural or steel-framed buildings.

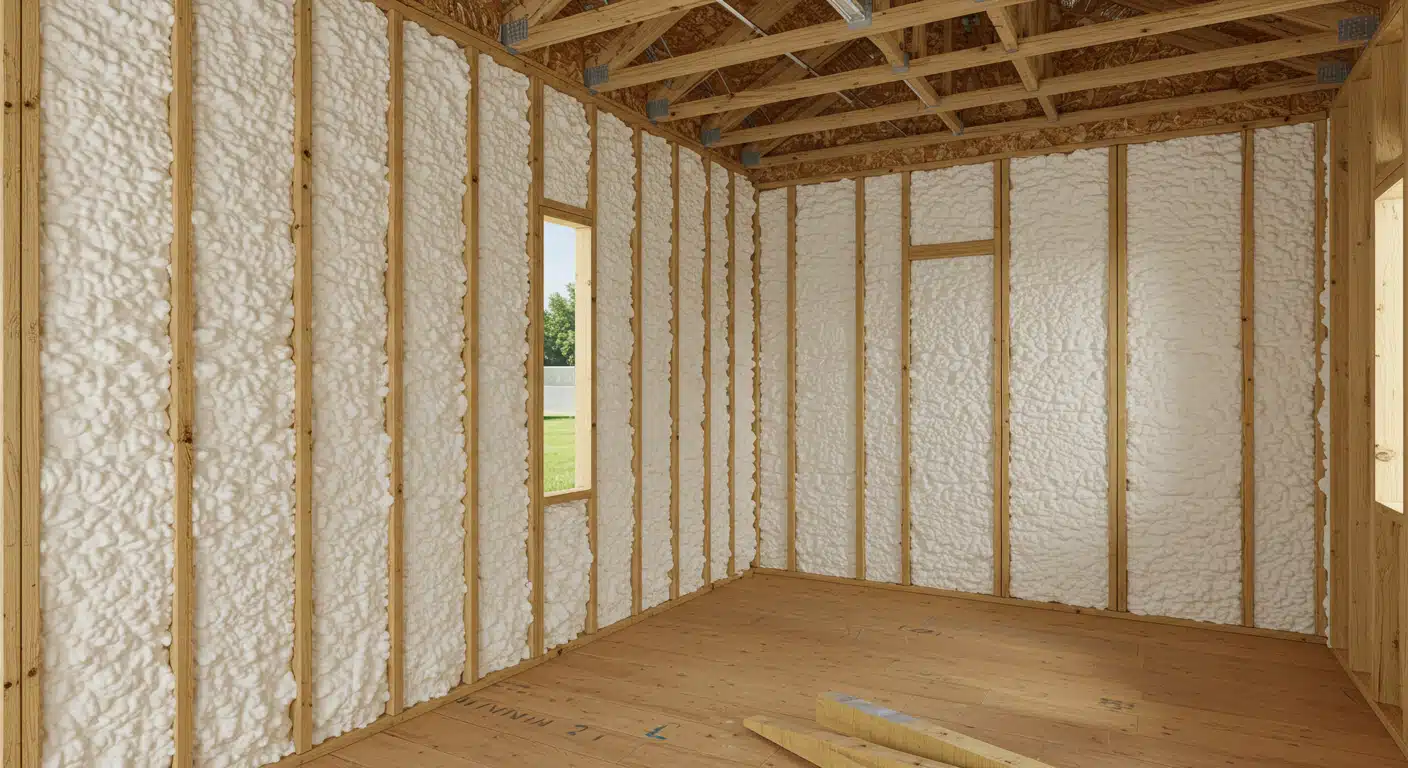

- New Construction Spray Foam: Offers thermal control from the ground up, especially important in modern energy-efficient builds.

Common Questions Before Choosing Spray Foam Insulation

Is closed cell foam worth the higher cost in cold climates?

Yes. It minimizes heat loss, prevents ice dam formation, and reduces heating system runtime.

Can open cell foam be used in roof decks in extreme climates?

Only with additional vapor control strategies, which can increase total system cost.

What’s the ideal thickness for closed cell spray foam in walls?

2 to 3 inches is typically enough to meet or exceed code minimums and resist condensation.

How long does spray foam last in harsh conditions?

Closed cell foam can last 30+ years when properly installed and protected from UV light.

Are there any climate zones where open cell performs well?

Mild, dry climates with little seasonal fluctuation are more forgiving for open cell insulation.

Get Expert Insulation Guidance

For detailed consultation and on-site evaluation, contact Rib Spray Foam Company. Every recommendation is based on years of real-world installation across Colorado’s harshest seasonal swings.

Phone: (970) 518-2883 Email: [email protected]

FAQs

Can closed cell foam be installed in freezing temperatures?

Yes, using winter-grade spray formulas and pre-warming surfaces ensures proper adhesion.

Does closed cell foam prevent all moisture issues?

No. While it resists vapor, leaks or poor flashing can still cause moisture problems if not addressed during installation.

What kind of prep is required before foam installation?

Surfaces must be dry, dust-free, and at the correct temperature range. Any gaps or penetrations should be sealed.

Will spray foam crack or shrink over time in extreme weather?

Closed cell foam remains stable under temperature stress. Minor movement can occur if surfaces shift structurally.

Can I combine spray foam with other insulation types?

Yes, hybrid assemblies using rigid foam or fiberglass can optimize cost and performance when done correctly.